Did you know that the origins of the golf ball can be traced back to ancient times?

It’s fascinating to uncover the historical materials used to create the very first golf balls.

Imagine playing with a ball made of leather pouches stuffed with feathers!

These early golfers relied on their skills to navigate the courses, as these handmade balls had limited distance and accuracy.

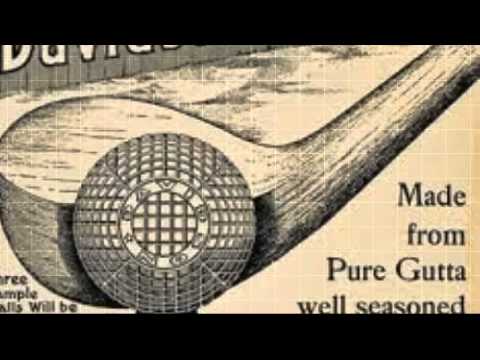

But as time went on, advancements in technology led to the development of the first modern golf ball, made from a material called gutta-percha.

This breakthrough allowed golfers to achieve greater distance and control.

Over the years, the golf ball design continued to evolve, with the introduction of rubber and the use of different materials like Surlyn and Urethane.

Today, golf balls are meticulously crafted to optimize performance on the course.

Join us as we delve into the fascinating history of golf balls and discover the historical materials that paved the way for the modern game.

Table of Contents

Related Video: "The History of Golf" by Sarahlevine11

Key Takeaways

- The first golf balls were made of leather pouches stuffed with feathers, which limited distance and accuracy.

- The development of the gutta-percha ball, made from the sap of the Gutta Percha tree, offered improved durability, consistency, and control.

- The introduction of rubber had a significant impact on golf ball technology, providing greater distance and control.

– Modern golf balls are made from materials like Surlyn and Urethane, which offer a balance between distance, control, spin, and feel.

Leather Pouches Stuffed with Feathers

The first golf balls were made of leather pouches stuffed with feathers, creating a unique and fascinating piece of sports history. These early golf balls were crafted by hand, with the leather pouches carefully sewn together to create a round shape.

Inside the pouches, a mixture of tightly packed feathers was inserted, providing the ball with its weight and consistency. Leather pouches were the ideal material for golf balls during this time period because they were readily available and durable. Feathers were chosen as the filling material because they provided the necessary weight for the ball to fly through the air. The feathers were carefully selected and packed tightly inside the pouch to ensure a consistent and reliable flight path.

While leather pouches stuffed with feathers were the most common type of golf ball in the early days of the sport, alternative materials were also used. For example, some golf balls were made from wooden cores covered in leather, while others were made from compressed cotton.

Transitioning into the subsequent section about ‘gutta-percha: the first modern golf ball’, it became clear that the leather pouches stuffed with feathers were a significant step in the evolution of golf ball technology.

Gutta-Percha: The First Modern Golf Ball

Imagine yourself stepping onto the golf course, ready to tee off with a Gutta-Percha ball that offers unmatched distance and control, allowing you to confidently conquer each hole. This revolutionary golf ball is made from the sap of the Gutta Percha tree and marked a significant shift in the evolution of golf equipment.

Here are four key aspects to understand about Gutta-Percha and its impact on the game:

- Gutta percha manufacturing process: The sap of the Gutta Percha tree is collected and heated until it becomes malleable. It’s then molded into a spherical shape and cooled down. This process ensures consistency in the ball’s size and weight, providing golfers with a reliable tool for their game.

- Gutta percha vs feather-filled golf balls: Unlike the previous feather-filled balls, Gutta-Percha offered improved durability and consistency. It delivered greater distance due to its solid construction, making it easier to control shots and achieve longer drives.

- Enhanced playability: The Gutta-Percha ball’s smooth surface allowed for more precise control of spin, making it possible to shape shots according to the golfer’s intention. This newfound control gave players a competitive edge on the course.

- Increased popularity: With its superior performance, Gutta-Percha quickly gained popularity among golfers. The new ball’s ability to provide consistent and reliable play led to its widespread adoption and revolutionized the game of golf.

As golfers embraced the Gutta-Percha ball, it paved the way for the introduction of rubber, which further improved the performance of golf balls.

The Introduction of Rubber

After Gutta-Percha revolutionized the game of golf, a new material made its debut on the course – rubber. The introduction of rubber had a significant impact on golf ball technology.

With its elastic properties, rubber provided a new level of distance and control to golfers. The manufacturing advancements in rubber also allowed for greater consistency in the production of golf balls.

Rubber, being more resilient than Gutta-Percha, allowed golf balls to achieve longer distances when struck. Its elasticity also provided a softer feel upon impact, enhancing the golfer’s ability to control the ball’s flight and spin. This innovation quickly gained popularity among golfers, as they saw their shots improve with the use of rubber golf balls.

Additionally, the advancements in rubber manufacturing techniques allowed for more consistent production of golf balls. This meant that each ball had a similar weight and size, resulting in predictable performance on the course. Golfers no longer had to worry about variations in the ball’s characteristics affecting their game.

As rubber took center stage in golf ball technology, it set the foundation for future developments in ball design. The introduction of rubber was a crucial step in the evolution of the golf ball, paving the way for further innovations and improvements in the years to come.

The Evolution of the Golf Ball Design

From the early days of gutta-percha and rubber, golf ball design continued to evolve, with manufacturers experimenting with new materials and construction methods to improve performance. Golf ball compression technology played a crucial role in this evolution. Manufacturers discovered that by varying the compression of the ball, they could alter its distance and feel. Higher compression balls, which were harder and denser, provided more distance but less control, while lower compression balls offered improved control but sacrificed some distance. The impact of dimple design on golf ball performance was also explored. Dimples were found to reduce drag and increase lift, allowing the ball to stay in the air for longer and travel farther. As a result, golf balls with different dimple patterns were developed to optimize performance in various weather conditions. These advancements in golf ball design laid the foundation for the modern golf ball, from surlyn to urethane. The subsequent section will delve into the further improvements made in golf ball technology.

The Modern Golf Ball: From Surlyn to Urethane

The modern golf ball has undergone such a dramatic transformation that it’s hard to believe it’s the same sport. With advancements in golf ball materials and technology, today’s golf balls are a far cry from their predecessors.

Golf ball materials have evolved significantly over the years. Surlyn, a type of ionomer resin, was introduced in the 1960s and quickly became popular due to its durability and affordability. It provided a good balance between distance and control. However, as technology advanced, golf ball manufacturers started experimenting with different materials to enhance performance.

One of the most significant advancements in golf ball materials was the introduction of urethane covers. Urethane, a type of thermoplastic elastomer, offered greater spin control and a softer feel. This allowed golfers to have more control over their shots and improved their ability to shape the ball in flight. Urethane covers also provided better greenside control, allowing for more short game finesse.

Technological advancements have also played a crucial role in improving golf ball performance. From aerodynamics to compression, manufacturers have used cutting-edge technology to enhance the distance, accuracy, and feel of golf balls. Computer simulations and wind tunnel testing have allowed for the optimization of dimple patterns, resulting in better lift and reduced drag.

The modern golf ball has come a long way from its humble beginnings. With advancements in golf ball materials and technology, golfers can now enjoy improved performance and enhanced control on the course.

Frequently Asked Questions

What were the earliest forms of golf balls made of before leather pouches stuffed with feathers?

Before leather pouches stuffed with feathers, the earliest golf ball designs were made of wood or other hard materials. However, the introduction of gutta percha had a significant impact on the game, revolutionizing the ball’s performance and durability.

How did the introduction of gutta-percha as a golf ball material impact the game?

The introduction of gutta-percha as a golf ball material revolutionized the game. Early experiments with various materials paled in comparison to the impact of gutta-percha. Its durability and improved performance transformed the way golf was played.

Were there any other materials that were experimented with before rubber became popular?

Before rubber became popular, golf ball manufacturers experimented with various alternative options for materials. These experimental materials included feathers, wooden balls, and leather-stuffed balls, each offering unique characteristics and performance on the golf course.

Can you provide examples of different designs that were used during the evolution of the golf ball?

Step into the fascinating world of golf ball evolution. Marvel at the myriad designs that emerged – from feather-filled leather pouches to the modern marvels of today, incorporating materials like urethane and titanium. Witness how technology transformed this humble sphere into a high-performance wonder.

What are some of the advantages and disadvantages of using Surlyn and Urethane in modern golf ball construction?

The advantages of surlyn in modern golf ball construction include its durability, distance, and affordability. However, it may lack the spin control and feel of urethane, which offers better control and a softer feel but is more expensive.